Product quality validation and analysis

Largest electrical switchgear manufacturer in the UK & Ireland

With over 30 years’ experience, E+I Engineering is the largest electrical switchgear manufacturer in the UK & Ireland, pioneering unique in-house integrated power solutions tailored to each individual client project. E+I Engineering’s switchgear range provide a complete power distribution solution to its client.

Founded in 1986 by Philip O’Doherty, the company is headquartered in Burnfoot, Co. Donegal with over 1,000 employees at present. Their 300,000 sq ft facility in Burnfoot was purpose built to house both the switchgear and Powerbar production lines.

Patented range of busbar trunking

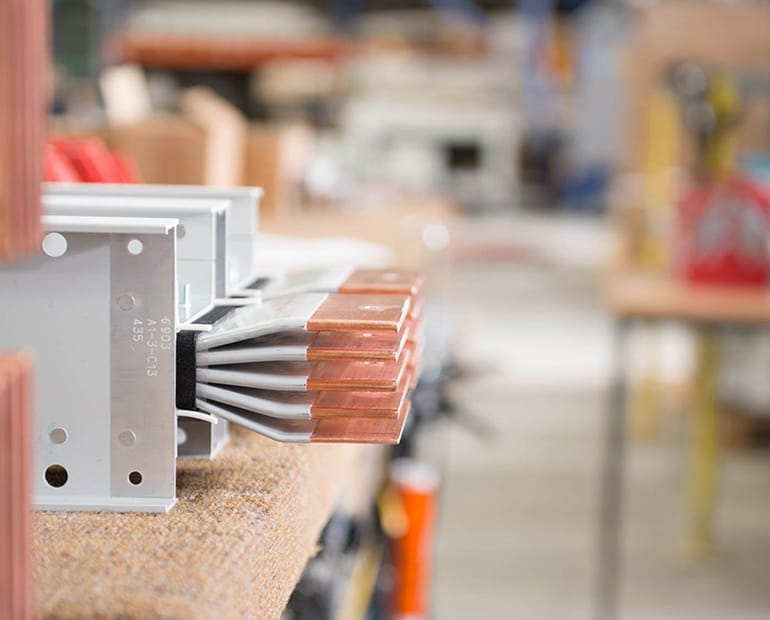

Powerbar is E+I Engineering’s patented range of busbar trunking, designed to deliver power to electrical loads. The Powerbar range is manufactured using state of the art technology and innovative manufacturing processes that ensure it is the most efficient and reliable busbar trunking solution on the market.

An Electrostatic epoxy powder coating system is used to insulate E+I Engineering’s busbar. Regular independent testing of production and developmental parts is essential for quality and validation purposes. On occasion production and developmental parts do not meeting industrial requirements and require specialised analysis to locate faults. In addition, where product failure has been observed by their clients, a rapid independent analysis is required. This is to ensure the production process quality and establish if failure was independent of the product and related to external factors.

>2,500

employees globally

34

years in business

3

manufacturing locations

“E+I Engineering’s partnership with CREST has added a new dimension to the company, offering an independent source of expertise that protects and improves upon the quality of our metallic coating systems and application process. The high quality of analysis and validation services provided by CREST has truly strengthened our product offering, ensuring reliability, efficiency, and safety within our Powerbar range.”

Gerard O’Hagan

Metal Coatings Manager, E+I Engineering Group

The E+I Engineering Group & CREST Technology Gateway partnership

E+I Engineering, globally recognised as leaders within the power distribution industry, require independent validation of their products. Since moving to DIT (now TU Dublin) in 2004, CREST has worked with E+I Engineering’s Powerbar production team to assess and validate the metallic coating systems and application process. In the event of production parts failing, as determined by quality control onsite or in CREST, metallurgical coating analysis is performed.

The CREST team use microscopy, spectroscopy and other analytical techniques to assess failure sources. CREST then identifies where the fault arose (either in-house or in-use) allowing the production team at E+I Engineering to solve the issue. E+I Engineering has a certified quality management system which ensures the high quality of their products and services. From the development process to the finished product their continuous improvement process includes all involved, from the supplier and the employee to the customer. Regular testing, certification and third party inspections ensure and provide independent verification of E+I Engineering’s compliance with industry standards.