A wearable system to measure joint stiffness from arthritis

ActionSense Ltd

Based in the city of Derry in Northern Ireland, ActionSense Ltd, was established in 2015 as a result of a strategic collaboration between academics, clinical specialists in Rheumatology and product development experts. The Company is as a spin-out of Ulster University.

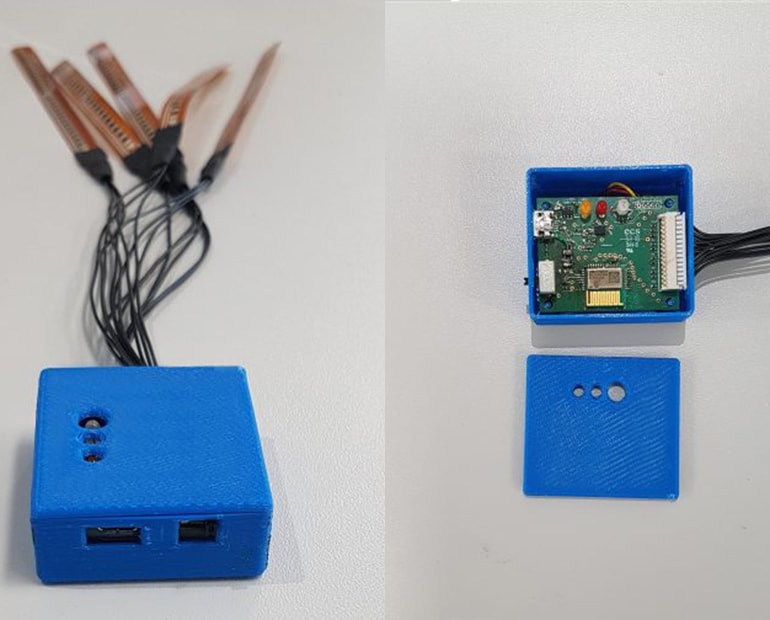

Dataglove Control Unit Design

ActionSense Limited has licensed technology from the University of Ulster for a glove designed to assess the stiffness of the joints in the fingers of patients suffering from various forms of arthritis. The glove works by positioning bend sensors on each finger joint in order to measure joint stiffness. The original proof of concept had overly complex electronics, so the client engaged WiSAR to design a smaller lower cost version. This required the development of a control unit, to be placed on the wrist, which collects data from each bend sensor and sends the data wirelessly to a client device for analysis.

1

Irish company

1

cross-border collaboration

2

Innovation Vouchers

“We were introduced to the WiSAR Technology Gateway at an early stage of the company’s development to produce working prototypes in the requisite form factor. These have been used in successful field trials with rheumatoid arthritis patients under clinical supervision. Going forward we plan to use WiSAR to develop further iterations of our electronics and firmware to support larger batch production.”

Dr Joan Condell

CEO, ActionSense Ltd

The ActionSense & Wisar Technology Gateway partnership

The project was funded using two Innovation Vouchers supplemented by direct funding from the Company. A proof of concept prototype was developed to process the signals from bend sensors fitted into the fingers of a glove and to transmit the corresponding data in real time. There are five sensors used in each glove, one for each finger. The sensors consist of a coated substrate that changes in electrical conductivity as they are bent. The wrist control unit, developed by WiSAR, was designed to gather the sensor data and to stream the readings every 25 milliseconds. Firmware for the client device was developed to receive the sensor data and display it on a computer using a serial terminal program. In the first iteration of the firmware an off the shelf USB-BLE dongle was utilised as the client device, a second iteration enabled streaming directly to a mobile phone or any Bluetooth Low Energy (BLE) client. The first prototype was delivered to the client for testing.

Subsequently, a second innovation voucher was used to further develop the initial prototype with the objective to reduce the overall dimensions of the control unit PCB and to enable production at a contract manufacturer. A 50% size reduction was achieved by replacing some of the main components on the first prototype with smaller footprint components and by utilising a multilayer PCB. The PCB board was designed to hold all components, excluding the bend sensors, and a batch professionally manufactured. Finally, a 3D printed case was designed and printed by WiSAR to house the prototypes. The housing contains slots for the switch, USB socket, bend sensor plug and LEDs.

The outcome from the work carried out by WiSAR was the deployment of working prototypes which enabled ActionSense to perform field trials and gather real time measurements from arthritis patients.